JT Sprockets

World's No. 1 Aftermarket Sprocket Manufacturer

The JT motorcycle sprockets' factory is today the largest and most advanced in the

world. It is fully equipped with high accuracy machinery, including the latest generation

of CNC computer design and computer controlled metal cutting equipment. JT is producing

a full range of sprockets for the aftermarket as well as for the OEM.

The essence of a high quality sprocket is in the high precision of manufacturing

and the inherent quality of the material. Through accurate machining and by using

only the best grade of C45 High Carbon steel for rear sprockets and SCM415 Chromoly

steel alloy for front sprockets, JT ensures Maximum Durability performance for both

Drive chain and sprockets.

JT manufactures sprockets the right way, by hobbing, machining and drilling. This

is the only proven way to achieve the closest of tolerances and the best teeth profiles.

Heat treated and hand finished to perfection, all JT sprockets meet or exceed the

highest possible quality standards set for the motorcycle industry. Each sprocket

goes through up to 25 production stages and 10 individual quality controls checks

before it is ready to leave the factory.

JT designs and produces 12 million sprockets a year for all makes and models of

motorcycles. The current range is over 2500 types of steel or 7075T6 aluminium alloy

and many items combine two or more different fittings into one sprocket.

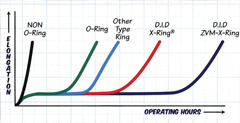

D.I.D SUPER HEAVY DUTY X-RING® ZVM-X

D.I.D’S ZVM-X-RING® IS THE FORMULA FOR MAXIMUM LONG LIFE IN X-RING® TECHNOLOGY

D.I.D has redesigned the shape of the X-Ring® to maximize wear resistance of the

new 530ZVM-X and 525ZVM-X chains. These two models have also been beefed up in tensile

strength to make them the ultimate chains for today's high performance sport and

sport touring motorcycles. The new ZVM-X-RING retains all the low friction, high

performance characteristics of the standard X-Ring® while providing a significant

increase in wear resistance and overall life of the chain.

Wear Resitance Chart

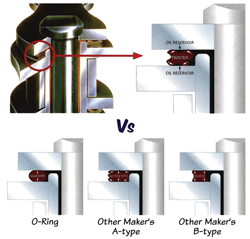

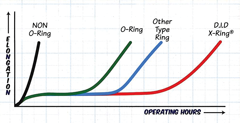

D.I.D HEAVY DUTY X-RING

D.I.D’S patented X-Ring® construction reduces friction by twisting between

the side plates instead of being squashed. Normal O-Rings and other makers' modified

O-Rings have squashed points that increase friction. The twisting action of the

X-Ring® disperses the pressure and minimizes power loss.

The X-Ring's four contact points greatly increase its sealing performance. This

keeps the dirt out and the lubrication in much better than any other O-Ring. The

D.I.D X-Ring® has the greatest wear resistance of any other type of O-Ring or non

O-Ring chain.

Wear Resitance Chart

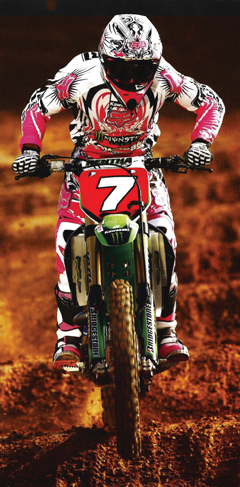

D.I.D CHAIN IS THE CHAMPION FOR SUPERCROSS AND MOTOCROSS

- D.I.D ER chain is designed exclusively for racingctory Supercross and Motocross

Teams

- 520MX chain has higher tensile strength for maximum performance and is ideal for

muddy/sandy conditions

- D.I.D's exclusive SDH pin treatment is the secret behind the superior performance

of our 520ERT2, 520MX and all NZ series chains

- SDH hi-tech pin treatment forms an extremely hard chromium carbide layer on the

pins surface while maintaining a soft inner core

- SDH treated pins have extreme impact strength while maintaining outstanding shock

absorption

- SDH creates a chain with superior wear resistance, antioxidation properties and

performs well against invasion of hard foreign materials

UNIBEAR High Quality Chains

Uni-Bear chain has been manufactured to a high standard using specialised C.N.C.

chain production equipment. The outer links and bushes have been polished to give

smooth running with reduced friction. Each part of the chain has been hardened for

maximum wear resistance and then final anti corrosion material has been applied

to all surfaces. The lubricating film on the surface of the chain will provide excellent

first time wear resistance.